Magistral Transit LLC

Russian company

Company history

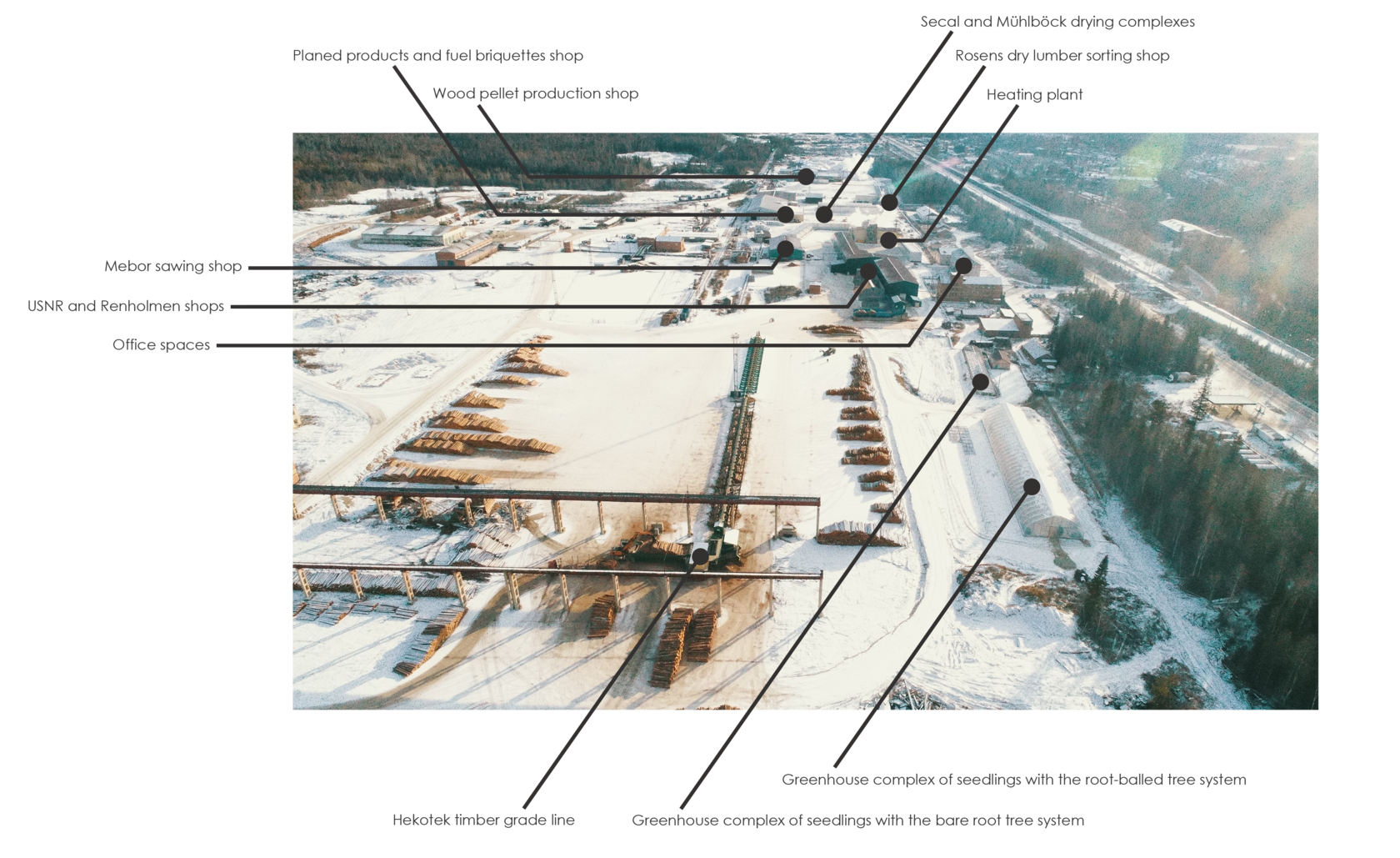

Magistral-Transit LLC was founded in 2007 as a logging company. In 2013, a full-cycle timber industry complex was created on its basis. The main focus was the production of dry lumber and planed products with a quality that meets export requirements.

Thanks to more than 30 years of experience in the field of woodworking, efficient production was established in the shortest possible time and systematic development was ensured. By 2022, the company’s production capacity amounted to 360,000 m3 of sawlogs per year.

Thanks to more than 30 years of experience in the field of woodworking, efficient production was established in the shortest possible time and systematic development was ensured. By 2022, the company’s production capacity amounted to 360,000 m3 of sawlogs per year.

Much has changed in the world since 2007, but our partners and customers can be sure that Magistral-Transit is developing steadily, keeping up with the times, increasing production capacity and improving the quality of goods.

We use modern machinery and equipment, monitor the safety of working conditions, and adhere to environmental friendliness, the main principle of our production. Reforestation in Siberia is an integral part of our work.

Manufacturing process

Our products go through all stages of processing: from harvesting work to shipment of finished products. 100% of technological waste such as bark, sawdust and woodchips are used as raw materials for biofuel production, as well as for internal needs of the company.

All machinery, equipment and production technologies comply with international standards and are approved by the international community. Our company is registered in the Unified State Automated Information System for Timber Accounting. The main purpose of the system is to control logging, production, import, export and domestic sales of wood, including lumber.

All machinery, equipment and production technologies comply with international standards and are approved by the international community. Our company is registered in the Unified State Automated Information System for Timber Accounting. The main purpose of the system is to control logging, production, import, export and domestic sales of wood, including lumber.

Withdrawal and inventory of timber cutting areas

A set of measures carried out before deforestation for logging and sanitary purposes or before clearcutting of forest stands.

- Analysis of the felling plan and forest land conversion

- Identification of areas for logging, development of withdrawal plan

- Preliminary inspection of the cutting area

- Tree marking and recalculation by thickness, species and categories

- Stumpage appraisal

- Timber distribution indicating the yield of specific logs and size categories

- Formation and placement of the forest declaration on the website of the Federal Forestry Agency

- Determination of the total wood supplies before deforestation

Logging

Logging is carried out on a pre-allocated and agreed area. For each area a flow chart is prepared with the place of logging, type of logging, time of its implementation, area, and inventory characteristics of the forest stand. The flow chart is accompanied by skidding trails, landing and the place where the crew is parked.

JOHNDEERE 1470G

JOHN DEERE 1910G

Cut-to-length involves the use of a harvester and a forwarder. The process flexibility minimizes negative environmental impacts.

Harvester cuts and processes trees. A hydraulic saw cuts the trunk of the tree from the base, then the trunk is passed through rollers, special knives cut off the limbs.

The harvester control system measures the length and diameter of the tree and determines the total volume of cut timber. The information is recorded on the onboard computer, which calculates the optimal sizes of future logs.

The forwarder is designed for skidding processed logs to the loading area.

The JD Link remote monitoring system allows to track the location of the machine and its operating parameters. The TimberOffice software allows to examine and evaluate in detail the trunk sizes, the amount of harvested timber and the assortment of processed logs on a specific plot for a selected period of time.

Harvester cuts and processes trees. A hydraulic saw cuts the trunk of the tree from the base, then the trunk is passed through rollers, special knives cut off the limbs.

The harvester control system measures the length and diameter of the tree and determines the total volume of cut timber. The information is recorded on the onboard computer, which calculates the optimal sizes of future logs.

The forwarder is designed for skidding processed logs to the loading area.

The JD Link remote monitoring system allows to track the location of the machine and its operating parameters. The TimberOffice software allows to examine and evaluate in detail the trunk sizes, the amount of harvested timber and the assortment of processed logs on a specific plot for a selected period of time.

Roundwood hauling

The company operates a system of operational control of vehicular traffic. We keep constant satellite control of the movement of each vehicle on the route, the schedule of its movement, arrival at the facilities and control points, as well as the control of fuel consumption.

MERCEDES BENZ short log truck

IVEKO-АМТ short log truck

Reforestation

We reproduce cut down, dead and damaged forests. We use natural, artificial and combined types of forest renewal.

We use all types of reforestation. Our company restore not only those parts of the forest where deforestation took place, but also those parts that were damaged by fire, wind, heavy rains, avalanching and other natural phenomena.

To promote natural reforestation we:

Grown pine seedlings

- Preserve the viable generation of major forest tree species that have regenerated under the forest canopy

- Take care of the undergrowth of forest stands of valuable tree species in areas not covered with forest vegetation

- Preserve valuable forest tree species during logging

- Mineralize the soil surface

Roundwood sorting

Logs are sorted by species, quality and diameters of the top end (according to geometric indicators such as crook, butt swelling, etc.). According to the parameters entered, the program selects the right stack.

Hekotek grade line

Hekotek grade line

The grade line consists of 62 sorting boxes and distributes timber up to 6 meters long.

Automation of the roundwood sorting process was provided by the Automatika-Vektor company.

Automation of the roundwood sorting process was provided by the Automatika-Vektor company.

USNR saw line

The USNR through-feed direct-flow circular saw line with chipping headrigs and a system for cutting side boards on the Catech TS-5 line is equipped for optimized cutting. The capacity of the line is 460,000 m³ of incoming raw materials per year.

Hedlunds sawlog feed line

USNR saw line

Before being fed into the head saw, sawlogs are passed through a 3D scanner with laser sensors. Based on the data obtained, each log is canted in the optimal position, which determines the maximum yield of lumber at the sawing stages. To optimize lumber yield, the USNR saw line uses log diameters of up to 50 centimeters.

We have created one compact lumber production site in a high-capacity automated saw line. It increased the lumber output, the quality of finished products, simplified the logistics of moving raw materials and finished products around the enterprise. Improving the quality of finished products due to the accuracy of sawing on new equipment, edging (the highest quality material is selected according to the scanner data),

preventing the formation of sawing defects.

We have created one compact lumber production site in a high-capacity automated saw line. It increased the lumber output, the quality of finished products, simplified the logistics of moving raw materials and finished products around the enterprise. Improving the quality of finished products due to the accuracy of sawing on new equipment, edging (the highest quality material is selected according to the scanner data),

preventing the formation of sawing defects.

Mebor band saw line

The band saw shop is characterized by less equipment required, which facilitates the operating process. It combines such advantages as a thin cut, the possibility of individual cutting of sawlog.

Mebor band saw

Mebor band saw

The band saw shop is aimed at cutting dimension-timber, that exceeds 36 centimeters in diameter.

Lumber drying

The company installed 23 convection drying chambers from two manufacturers. Lumber that has undergone the process of chamber drying becomes resistant to rotting, the wood becomes denser, and also less prone to change in shape and size.

Mühlböсk drying chambers

Secal drying chambers

The chambers dry the wood by means of intensive air heat exchange, which guarantees the removal of moisture with minimal geometrical deviations in the material. After drying, the wood does not crack, bend or warp, even when processing a thin product.

The company installed Austrian Mühlböck drying chambers with a capacity of 200 m³ and Italian SECAL chambers with a capacity of 150 m³.

The company installed Austrian Mühlböck drying chambers with a capacity of 200 m³ and Italian SECAL chambers with a capacity of 150 m³.

Lumber sorting

Lumber sorting is represented by two high—precision automated lines: Rosens for dry lumber and Renholmen for natural moisture lumber.

FinScan scanning system

Sorting boxes

The Rosens grade line processes 100 boards per minute, distributing them into 40 boxes. The FinScan scanning system monitors the quality of lumber and detects its defects, which ensures high sorting accuracy and optimizes the entire process. The ReeR safety light curtain protects operators from accidents at automated production sites.

The Renholmen grade line, with a capacity of up to 100 stops per minute, distributes lumber into 50 boxes, which allows the line to be used on a flexible schedule.

The Renholmen grade line, with a capacity of up to 100 stops per minute, distributes lumber into 50 boxes, which allows the line to be used on a flexible schedule.

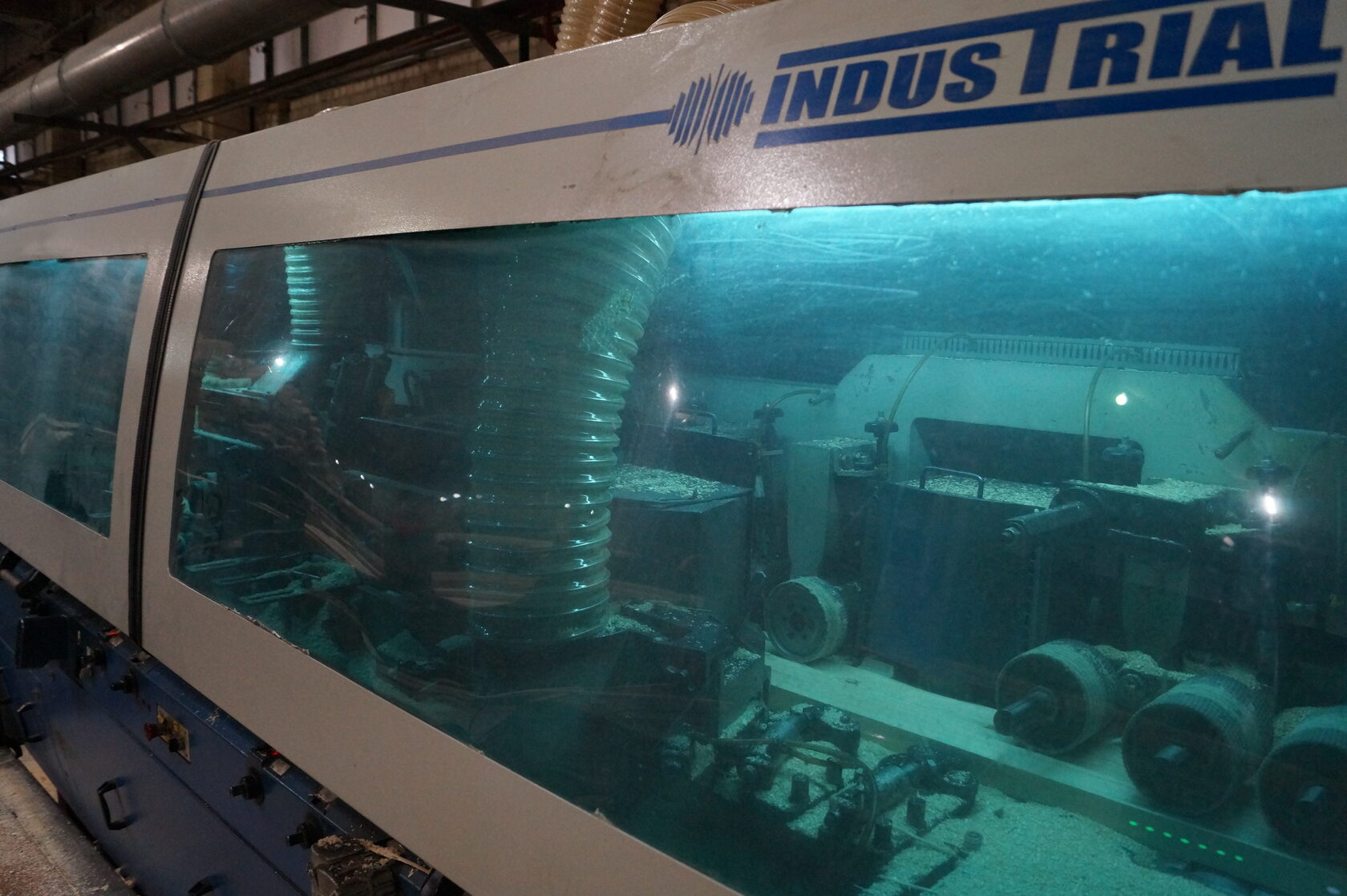

Planing

In the planing shop, German equipment WEINIG for processing solid timber and wood-based materials is installed. The company also operates Industrial four cutter from Leadermac. The cutters were developed with the specifics of the production environment in mind.

Leadermac woodworking equipment

WEINIG woodworking equipment

Briquetting

In pursuit of 100% waste-free production, we try to use all types of waste from production. Fuel briquettes are made from dry chipped sawdust on the German equipment of RUF, specializing and leading in the field of briquetting.

RUF briquette production shop

RUF briquette production shop

Wood pellet production

For wood pellet production, we use chipped wood waste, which is cleaned and dried in the pellet shop. CPM Europe equipment from the Netherlands is installed for wood pellet production. CPM is a world leader in the production of equipment for pelleting and chipping a wide range of wood. Production capacity of the shop is 5 tons of pellets per hour.

A1 wood pellets

Wood pellet production shop

The pellet shop is equipped with Firefly AB fire protection system. There are several high-risk areas in the fuel pellet production process where fires or dust explosions may occur. Firefly AB uses infrared detection combined with water spray extinguishing to achieve effective protection of the fuel pellet production process.

Loading and shipping products

Delivery is made in railroad cars, shipping containers and by truck. Shipment of products in railroad cars and containers is made on the company’s access railroad with the help of loaders.

Loading of packaged products

Loading of packaged products

Heat

The heating plant provides the operation of the drying complex and heats the entire enterprise. Such waste from woodworking as bark, wood chips and sawdust are used as fuel. The company has three solid fuel boilers.

Safety

The safety of our employees and guests comes first. We have created a working environment that meets global standards. Advanced, individual and protective equipment, regular briefings and trainings are prerequisites for building a safe environment.

Territory

The company’s production site is monitored by video surveillance in real time. The territory is fenced and guarded. The checkpoint is equipped with a verification and identification system for scanning and facial recognition. We believe it’s extremely important to trust your staff, but when it comes to safety, it’s better to be overly cautious. Keeping employees alive and healthy is the key to success. Our employees know that we do not lower the level of protection of working conditions.

Equipment

We use modern equipment that not only meets all quality standards of the finished product, but also guarantees the safety of the operating personnel.

The saw line is automated, all potentially dangerous elements are operated in special closed compartments, and the line operators are located in a protected control room. The line also has special electronic fences that are built into the line control system and prevent the equipment from starting if these fences are open for routine inspection or replacement of parts.

Personal protective equipment

Employees of production units are provided with equipment to protect against harmful workplace factors in accordance with the specifics of the work: protective clothing for the temporary season, helmets, earmuffs, safety glasses.

FSC Certificates

Chain of custody certification (COC) allows you to trace each stage of the movement of wood and forest products from harvesting to its sale, to confirm the origin of wood from specific forest areas throughout the movement of wood materials and products from the forest or from the place of processing (when using recycled materials) to the end consumer. Certification is in accordance with FSC-STD-40−004.

Forest management certification (FM) is a type of certification for forest owners or managers who want their forest management to meet the requirements of the FSC Principles and Criteria. This certification is carried out according to the standards of the National Forest Management FSC and Forest Stewardship Council for the Russian Federation.